The Development of Sustainable Paint for Coil Coated Steel

Speaker

Jake Kramp PhD Student, M2A Coated PhD program - University of Swansea

Jake Kramp PhD Student, M2A Coated PhD program - University of Swansea

Speaker

Jake Kramp PhD Student, M2A Coated PhD program - University of Swansea

Jake Kramp PhD Student, M2A Coated PhD program - University of SwanseaThe development of the sol-gel process opened the possibility of utilising ceramic coatings at low curing temperatures. However, these coatings have drawbacks such as a tendency to crack, delaminate, and limited thicknesses (nm). Through the modification of the sol-gel chemistry it is possible to produce defect-free coatings that can be scaled up to a coil-coating line.

Throughout this presentation I will be discussing the development of sol-gel coatings, with a particular focus on:

Speaker

Evan Watkins Research Engineer - University of Swansea

Evan Watkins Research Engineer - University of SwanseaSpeaker

Marc Walker Photoemission Research Technology Platform Manager - University of Warwick

Marc Walker Photoemission Research Technology Platform Manager - University of WarwickSpeaker

Alex Cunliffe Post-Doctoral Research Associate - Manchester Metropolitan University, Department of Natural Sciences

Alex Cunliffe Post-Doctoral Research Associate - Manchester Metropolitan University, Department of Natural Sciences Speaker

Dr Wadood Hamad CTO - Seprify

Dr Wadood Hamad CTO - SeprifySpeaker

Dr Jonathan Ward Lecturer - Lancaster University

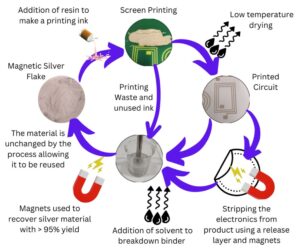

Dr Jonathan Ward Lecturer - Lancaster UniversityThere was 57Mt of electronic waste generated in 2022 of this less than 25% is currently recycled. The commercial recycling processes focus solely on the recovery of the precious metals at the expense of everything else. The silver ink we have formulated can create printed electronics using existing manufacturing methods such as screen-printing and recovered from products or manufacturing waste without using toxic highly-chemicals. The recovered silver can be reused in the manufacturing of new inks without further processing, creating a cost-effective closed loop system for circular printed electronics and reducing scope 3 emissions.

Speaker

Dr James Claypole Research Officer - Founder - Swansea University - AilArian

Dr James Claypole Research Officer - Founder - Swansea University - AilArianSpeaker

Dr James Claypole Research Officer - Founder - Swansea University - AilArian

Dr James Claypole Research Officer - Founder - Swansea University - AilArianSpeaker

Prof. Manish Tiwari University College London

Prof. Manish Tiwari University College LondonSpeaker

Prof. Ioannis Papakonstantinou Professor of Photonics and Nanofabrication - University College London

Prof. Ioannis Papakonstantinou Professor of Photonics and Nanofabrication - University College LondonInterfacial chemistry plays a pivotal role in the materials manufacturing industry. For instance, in composite materials, it governs the interactions between different constituent materials at their boundaries, thereby influencing their structural properties in terms of stability and durability. Additionally, interfacial chemistry is crucial in understanding how materials interact with the environment, ultimately determining their lifespan. A comprehensive grasp of interfacial chemistry is widely recognized as essential for advancing material manufacturing.

Surface-sensitive, in situ spectroscopic techniques such as soft X-ray photoelectron and absorption spectroscopy (XPS and NEXAFS) are powerful tools for investigating these phenomena. However, utilizing these techniques poses challenges due to the necessity of ultra-high vacuum conditions. Nonetheless, significant advancements in instrumentation have rendered these techniques indispensable for studying gas-solid interfaces.

In my presentation, I will illustrate the significance of interfacial chemistry in nanostructured carbon relevant to the painting manufacturing industry. Through specific examples, I will demonstrate how employing these methodologies can contribute to the development of superior materials.

Speaker

Associate Prof. Rosa Arrigo Associate Professor in Inorganic Chemistry - University of Salford

Associate Prof. Rosa Arrigo Associate Professor in Inorganic Chemistry - University of Salford